A heat exchanger is an equipment that facilitates the transfer of heat from one fluid to another. They can exchange temperatures between two or more fluids, including liquids, vapors and gases.

Heat exchangers come in various functionalities, and depending on their type, the heat transfer process can occur in gas-to-gas, liquid-to-liquid, or liquid-to-gas. It can also happen through a separating solid, which prevents direct fluid contact.

A wide range of heat exchanger manufacturers design them for use in heating as well as cooling processes.

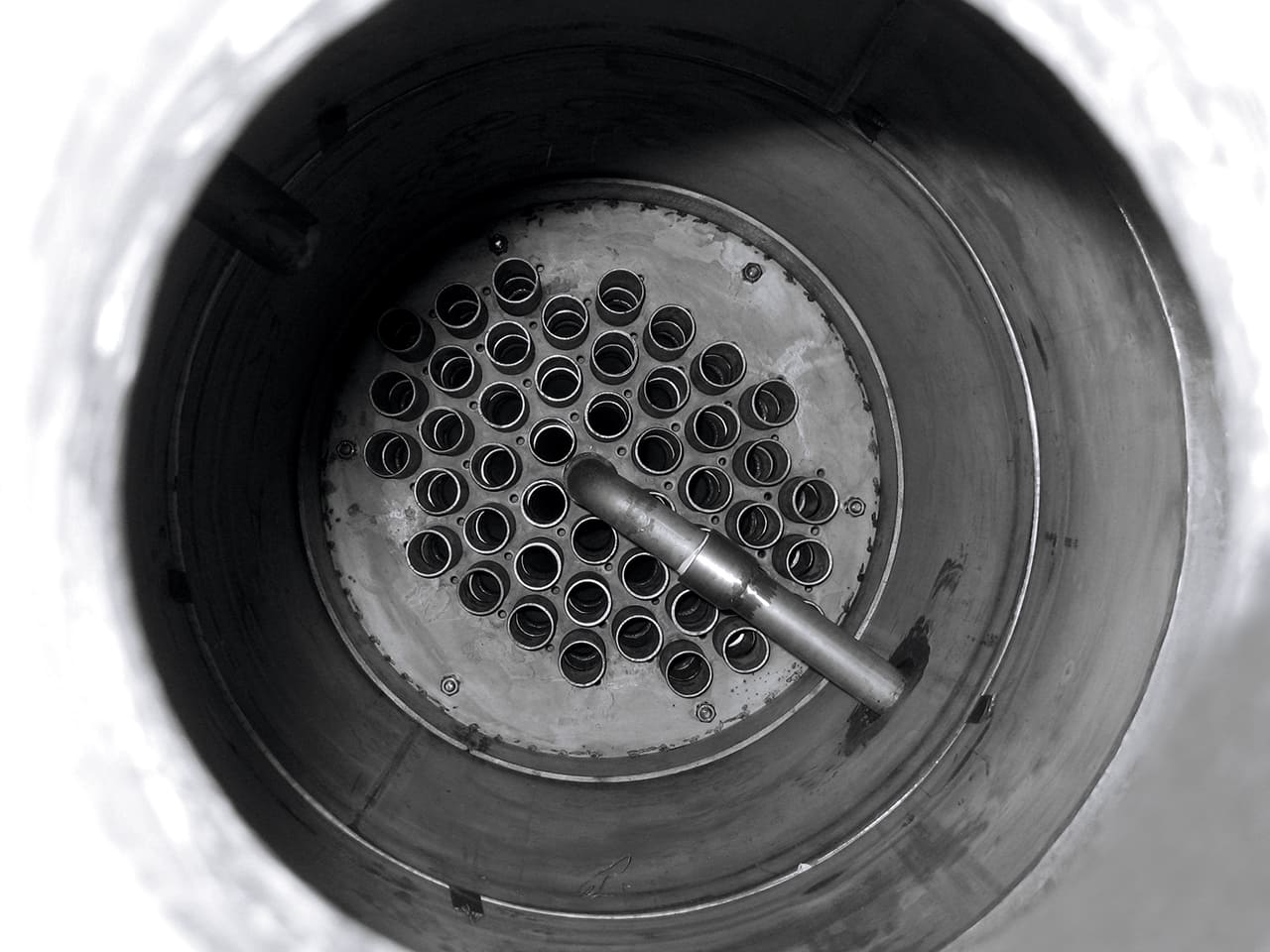

A shell and tube heat exchanger is one of the most common heat transfer equipment used in various chemical industrial manufacturing processes. It consists of tubes inside a cylindrical shell where fluids undergo the heat exchange process.

Heat is transferred between the two fluids through the tube walls, resulting in either cooling or heating of the fluids, depending on the specific application.

Heat exchanger suppliers design them to have a large surface area, allowing efficient heat transfer.

It is widely used in various industries, including chemical processing, oil refining, power generation, HVAC systems, pharmaceuticals, etc. The versatility of this heat exchanger type allows it to handle a wide range of temperatures and pressures, making it suitable for diverse applications.

In India, manufacturers and exporters make twin shaft dispersers that are commonly used in the mixing of thick pastes & high viscosity adhesives, homogenising rubber compounds, blending coatings and varnishes in the paint industry and processing high viscosity composites.

To conclude, a high speed disperser is used for its swift mixing ability and is well suited for applications that require quick dispersion while a twin shaft disperser is better for intensive mixing of high viscosity materials, which makes it ideal for demanding processes. Stalwart International is the best disperser manufacturer that designs, customises and provides maintenance services.

n corrugated tube heat exchangers, the efficiency and heat transfer coefficient are increased significantly compared to plain tube heat exchangers. Additionally, potential fouling is minimized, which makes supplying compact heat exchangers easier.

Stalwart International is one of the leading corrugated tube heat exchanger suppliers and exporters. We are a heat exchanger manufacturer who designs every piece of equipment precisely and customizes them depending on the requirement.

The main advantages of choosing a corrugated tube heat exchanger are increased heat transfer and a compact design, which reduces servicing costs.

Stalwart International is an ASME-certified industrial heat exchanger manufacturer that designs, exports and looks after the maintenance of corrugated tube heat exchangers in India. If you are looking for corrugated tube heat exchanger suppliers, contact Stalwart International – India’s best heat exchanger manufacturer.

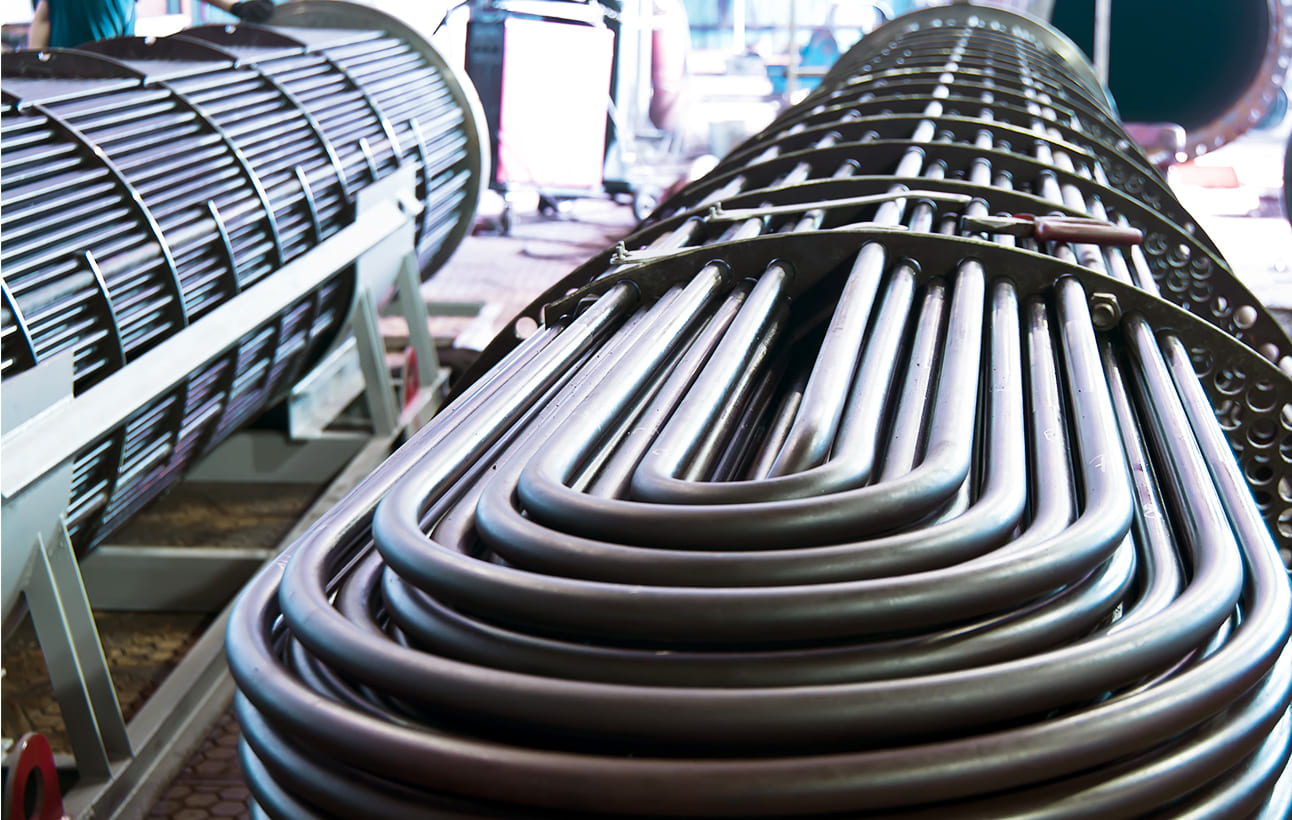

A U bundle heat exchanger is a specialised heat transfer device which has a U shaped tube arrangement that enables effective heat transfer between two fluids.

It consists of a bunch of U shaped tubes held by tube sheets inside an outer casing. The tubes’ U shaped design facilitates thermal contraction and expansion without excessive stress on the tubes.

The U tubes in a U tube bundle heat exchanger enable it to take up less volume than a straight tube heat exchanger, facilitating low-pressure loss. It also has other advantages like a high thermal efficiency, flexibility for various temperature differentials, ease of maintenance and adaptability to different process requirements.

They are widely employed in industries such as petrochemicals, chemicals and power generation. Stalwart International is an ASME-certified industrial heat exchanger manufacturer that designs, exports and looks after the maintenance of vertical shell and U bundle heat exchangers in India. If you are looking for a U bundle heat exchanger, contact Stalwart International – India’s best heat exchanger manufacturer.

A hairpin heat exchanger is a specific type of shell and tube heat exchanger that resembles the shape of a hairpin. It is very commonly used in various industrial applications.

This type of heat exchanger is ideal for applications that require specific temperature differences between the two fluids. The hairpin-shaped design allows thermal flexibility, reducing stress on the tubes.

The hairpin heat exchanger is widely used in chemical processing, petrochemical, oil refining and HVAC systems. The multitube hairpin makes the heat exchanger compact, making it suitable for applications with space constraints.

Stalwart International is an ASME-certified industrial heat exchanger manufacturer that designs, exports and looks after the maintenance of hairpin heat exchangers in India. If you are looking for heat exchangers, contact Stalwart International – one of India’s best hairpin heat exchanger manufacturers.

A floating head heat exchanger is a type of shell and tube heat exchanger which consists of a cylindrical shell containing a bundle of tubes, one end of which is connected to a floating head.

The floating head design allows the contraction of the tubes without being subjected to excessive stress. Heat is transferred through the tube walls, enabling efficient heat transfer.

The floating head heat exchanger is preferred in scenarios with a thermal stress risk because of differential expansion. This design simplifies maintenance and makes it suitable for multiple industrial applications like power plants, chemical processing, oil refineries, etc. There is also a variant called split ring floating head heat exchanger.

Stalwart International is an ASME-certified industrial heat exchanger manufacturer that designs, exports and looks after the maintenance of floating head bundle heat exchangers in India. If you are looking for a floating tube heat exchanger, contact Stalwart International – India’s best heat exchanger manufacturer.

Heat exchangers are used in various operations to regulate temperature and increase safety across multiple sectors, including Chemical, Pharmaceutical, Paint, Polymer, Textile, Specialty, Dye, oil, and petrochemical.

From careful selection of raw materials to rigorous testing using X-ray hydraulic, pneumatic, and penetration testing, we manufacture, install, and perform maintenance services to ensure seamless and secure functioning. As an industrial heat exchanger manufacturer in India, Stalwart International is accredited by leading regulatory organizations, like ASME (American Society of Mechanical Engineers) U, R, and ISO IMS.

WHAT WE OFFER

UNMATCHED EXCELLENCE AND RELIABILITY

CLIENTS' TESTIMONIALS

GOOD READS

Dynamic Blog